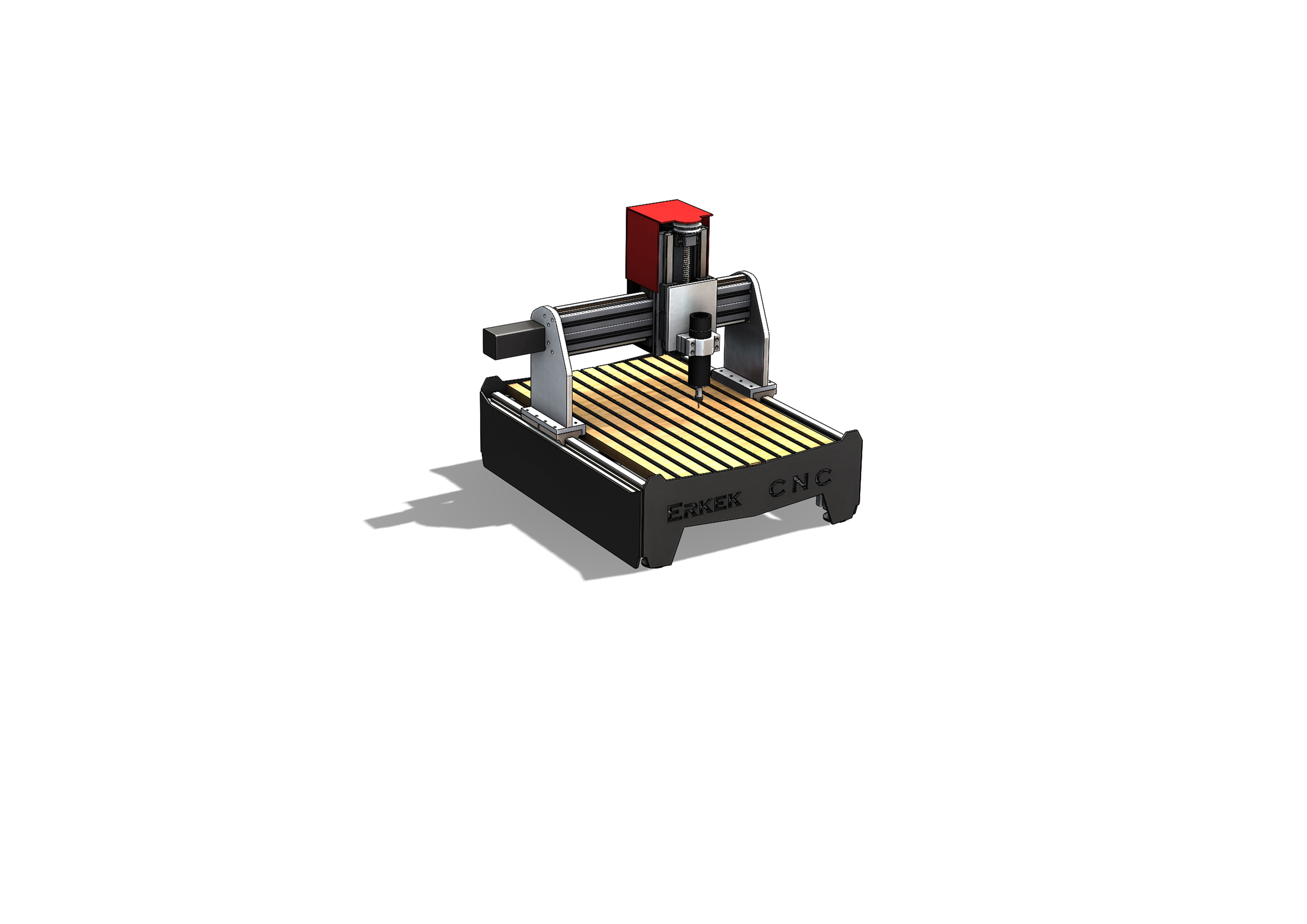

CNC Router and Multi-funcional Tools

Project Name:

Multi-functional Production Machine

Outcomes:

- A model of a 3-axis CNC router is created

- Understood mechanical design that considers precision and accuracy

Responsibility:

- Making design choices of CNC router including actuator and power transmission system, electronics

- Designind CNC router mechanical CAD design from Solidworks

- Conducting strain and stress analysis using Solidworks Simulations

- Creating new solutions to have different tools

Project Objectives:

- Developing a low-cost 3 axis CNC router for basic aluminum cutting for makers and DIYers.

- Expanding my machine parkour to have more material choices in my future projects.